Description

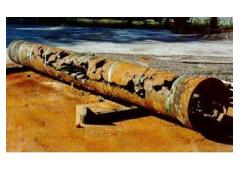

Corrosion inhibitors are essential additives in metalworking fluids (MWFs) to protect metal surfaces from degradation caused by corrosion. They help prevent the formation of rust and other types of corrosion, thereby extending the lifespan of equipment and improving machining performance. Here's how corrosion inhibitors work in metalworking fluids:

1. Protection Against Rust:

- Corrosion inhibitors form a protective barrier on metal surfaces, preventing corrosive agents such as water, oxygen, and contaminants from coming into contact with the metal. This barrier inhibits the electrochemical reactions that lead to rust formation, keeping the metal surface intact and corrosion-free.

2. Types of Corrosion Inhibitors:

- There are various types of corrosion inhibitors used in metalworking fluids, including:

- Passivation Inhibitors: These inhibitors work by promoting the formation of a passive oxide layer on the metal surface, which acts as a protective barrier against further corrosion.

- Film-Forming Inhibitors: These inhibitors create a thin film on the metal surface, effectively blocking the penetration of corrosive agents and preventing corrosion from occurring.

- Polarization Inhibitors: These inhibitors alter the electrochemical properties of the metal surface, making it less susceptible to corrosion by shifting the potential towards a more passive state.

- Volatile Corrosion Inhibitors (VCIs): These inhibitors release volatile compounds into the atmosphere, forming a protective layer on metal surfaces even in hard-to-reach areas.

3. Compatibility with Other Additives:

- Corrosion inhibitors in metalworking fluids are often formulated to be compatible with other additives, such as lubricants, emulsifiers, and anti-foaming agents. This ensures that the overall performance and properties of the MWFs are not compromised.

4. Application Methods:

- Corrosion inhibitors can be added directly to metalworking fluids during formulation or as a separate additive during use. They may also be incorporated into the MWF system through in-line dosing systems or central mixing units.

5. Performance Evaluation:

- The effectiveness of corrosion inhibitors in MWFs is evaluated through various laboratory tests and field trials. These tests assess factors such as corrosion resistance, film formation, stability, and compatibility with different metals and materials.

6. Environmental and Health Considerations:

- When selecting corrosion inhibitors for metalworking fluids, it's essential to consider their environmental and health impacts. Many modern corrosion inhibitors are formulated to be environmentally friendly, biodegradable, and free from harmful chemicals such as heavy metals and volatile organic compounds (VOCs).

In summary, corrosion inhibitors play a critical role in protecting metal surfaces from corrosion in metalworking fluids. By forming a protective barrier, these inhibitors help extend the lifespan of equipment, improve machining performance, and reduce maintenance costs. It's important to select the right type of corrosion inhibitor based on the specific application and environmental considerations to ensure optimal performance and safety.