Description

Overview

Mold is the casting billet forming equipment in continuous steel casting, and it is also the core equipment and key technology of continuous casting machine. Its function is to forcibly cool the high-temperature molten steel continuously injected into its inner cavity through the water-cooled copper plate to export its heat and to gradually solidify it into a casting billet with the required cross-sectional shape and billet shell thickness. And the casting billet, which is still in liquid state, is continuously pulled out from the lower nozzle of the mold to create conditions for casting billet to be completely solidified in the subsequent secondary cooling area.

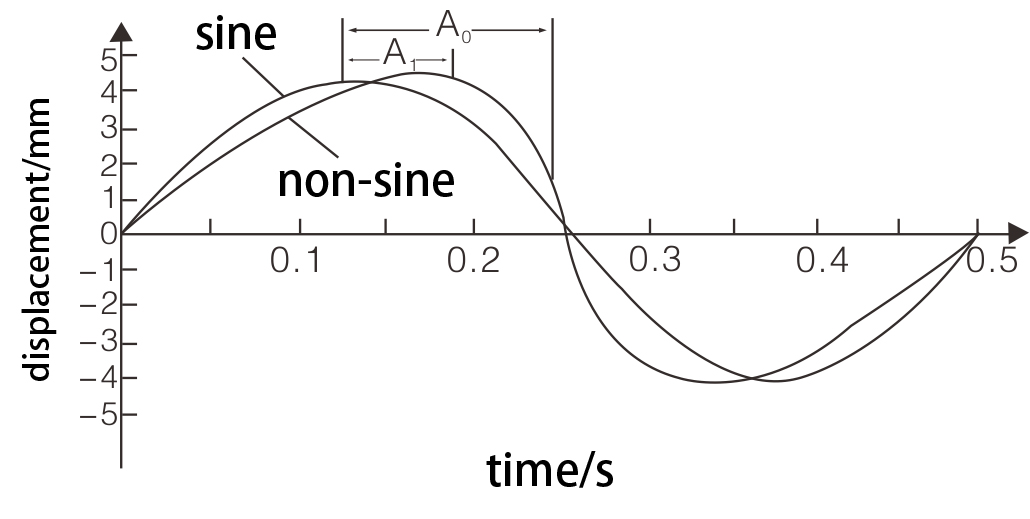

The main function of the mould oscillation device is to make the mould perform mechanical movement according to the given characteristics of amplitude, frequency and waveform deflection. The purpose is to facilitate demoulding and prevent the occurrence of sticking and breakout accidents due to the bonding of the casting billet with the copper wall of the mold during the solidification process.

MOC-K100 mould oscillation online monitoring system can three-dimensionally detect the positive and negative frequencies and waveform characteristics of the mould oscillation. The online changing data is provided in real time, which provides convenient and effective detection methods for on-site inspection personnel.

The functions of the system

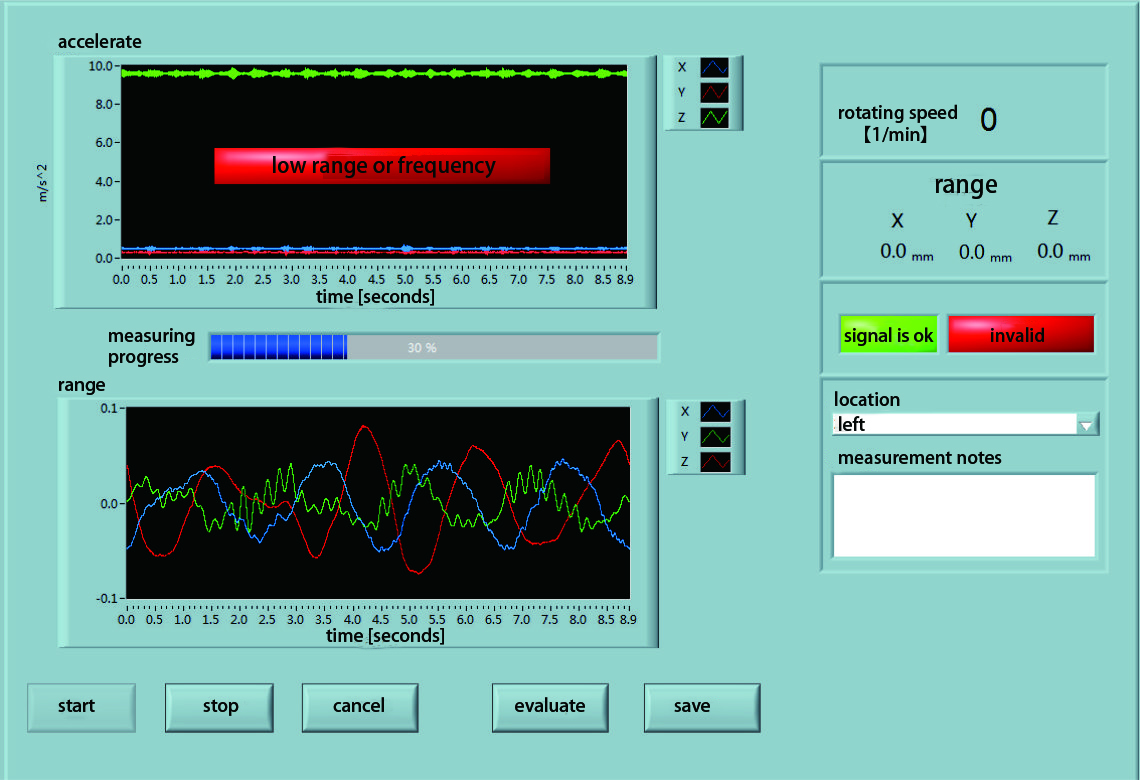

(1) Overview of monitoring parameters: Provides an overview of real-time monitoring parameters in the full screen, displaying all real-time data including oscillation parameters and process parameters.

(2) Time domain waveform: This function mainly displays the oscillation waveforms of multiple measuring points and one channel standard waveform in real time, and simultaneously displays the three elements of oscillation of each measuring point in real time.

(3) Waveform superposition: The difference between this function and the time domain waveform is that the waveforms of multiple measuring points are superimposed on a graph with lines of different colors on the same scale, and the oscillation difference of each channel can be calculated and displayed intuitively.

(4) FFT: This functional module completes the calculation and display of the oscillation spectrum in real time. It is used to evaluate the waveform distortion of the entire oscillation table and to determine whether there is a problem with the installation of the oscillation device.

(5) Bar graph: The oscillation of each measuring point is indicated by a bar graph of peak value and sensor gap voltage, which is more intuitive.

(6) Trend: After starting this module, the operator can search the historical records in the database, analyze the changing trend of each parameter, and use it to analyze the rationality of the steel quality and processing parameter settings for different steels under the oscillation conditions.

The parameters of the system

1. Number of measurement channels: According to the mold design, up to 16 sensors can be arranged

2. Sensor: three-dimensional oscillation sensing (X, Y, Z three axes)

3. Sensitivity: 1000mV/g

4. Frequency range: 0.04~10HZ

5. Frequency accuracy: ±0.01 Hz

6. Amplitude accuracy: 0.005mm

7. Transmission mode: wired digital transmission, wireless transmission

8. Host: 3U standard rack, handheld device

9. Sensor power supply: 24V.DC

10. Host power supply: 220V.AC/50Hz

Mold oscillation curve

Wuhan CenterRise M&C Engineering CO., Ltd.

more info, please contact

Mobile: +86 13995588597

Wechat/whatsapp:+86 15727288019

sales@whzfy.com